Nanjing is continuing to cultivate pilot projects for intelligent construction, accelerate the formation of new quality productivity led by scientific and technological innovation, promote the transformation and upgrading of the construction industry, and provide replicable and promotable Nanjing experience for the development of intelligent construction across the country. Recently, the list of intelligent construction pilot projects in Nanjing in 2024 was announced, covering affordable housing, schools and other housing construction projects. At the same time, as a new municipal engineering project of pipe corridor this year, the Binjiang Road comprehensive pipe gallery construction project in Xiaguan Binjiang Business District has also been selected into the list of 17 pilot projects.

Project Overview and Progress

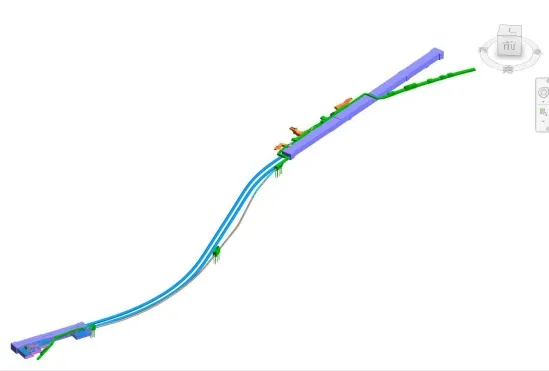

The Binjiang Road Comprehensive Pipe Corridor is an important municipal pipeline passage in the Gulou Binjiang Business District, with a total length of about 1,655 meters from Jinchuanhe West Road in the north to Longjiang Road in the south. In the planning stage, the project actively organizes the management structure and equips professionals to promote intelligent construction.

At present, the main structure construction of the pipe gallery is underway, and the main structure of the pipe gallery of the shield launch shaft, the relay shaft and the upper span of the subway shield section in the Fangjiaying work area has been completed; 70% of the pile foundation construction of the pipe gallery in the open-cut section of Nanjing West Railway Station has been completed; Fangjiaying work area for pile foundation construction; Synchronous completion of shield machine selection and segment processing.

Efficient integration of multiple monitoring subsystems

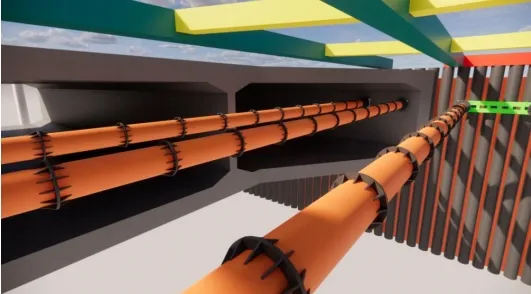

Build an intelligent construction management platform integrated with a new generation of information technology such as BIM technology and new construction control monitoring system. Efficient integration of multiple monitoring and management subsystems such as “man, machine, material, method, environment”, such as intelligent labor management, etc., to achieve comprehensive perception and real-time interconnection of engineering construction management.

Automatic collection and analysis of robot inspectionIn the construction process of the main body of the pipe gallery, the shield working shaft and the shield section, various construction robots and intelligent equipment applications are used. For example, the measured robot is used to measure the completed structure, and the detection data is automatically collected, shared and analyzed.

The project plans to use concrete leveling robots and concrete vibrating robots to replace manual labor in the main construction stage, improve construction efficiency and control project quality. After the completion of the project, the cleaning robot is used to protect the finished product.

In recent years, China has actively encouraged the construction of urban underground comprehensive pipe corridors. It is believed that with the pilot of intelligent construction in the construction of underground comprehensive pipe gallery, the wide application of new industrialization, informatization, intelligence and other technologies in the construction will further improve the level of urban infrastructure construction and ensure the healthy and sustainable development of the city.